In the world of mold manufacturing, achieving the desired surface finish and aesthetics is crucial in TPU (Thermoplastic Polyurethane) injection molding. TPU is a highly versatile material known for its excellent mechanical properties and flexibility. In this article, we will explore the importance of surface finish and aesthetics in TPU injection molding, and how mold manufacturing companies employ various techniques to achieve high-quality results that meet the aesthetic requirements of their customers.

Understanding Surface Finish in TPU Injection Molding

Surface finish refers to the texture and appearance of the molded part’s exterior. The surface finish can greatly impact the aesthetics, functionality, and overall quality perception of the final product. In TPU injection molding, achieving a desired surface finish is essential to meet specific design requirements and fulfill the expectations of end-users.

Tooling Design and Surface Texture

Mould manufacturers play a critical role in achieving the desired surface finish in TPU injection molding. The tooling design and construction are key factors that influence the surface texture of the molded part. Mold manufacturing companies utilize their expertise to carefully design the mold cavity and incorporate features that contribute to the desired surface texture, such as textured inserts or engraved patterns.

By specifying the appropriate texture and finish in the mold design, mold manufacturers can create the desired surface pattern, whether it is smooth, matte, glossy, or textured. The choice of surface texture depends on the intended purpose and aesthetic requirements of the final product.

Mold Surface Preparation and Conditioning

Effective mold surface preparation and conditioning are essential steps in achieving optimal surface finish in TPU injection molding. Mold manufacturing companies employ various techniques to ensure the mold surface is clean, free from defects, and properly conditioned before the injection molding process. This includes thorough cleaning to remove any residue or contaminants that could impact the surface quality of the molded part.

Mold manufacturers may also utilize surface treatments or coatings to enhance the surface finish and aesthetics of TPU injection-molded parts. Surface treatments, such as polishing or texturing, can provide a smoother or more textured appearance, depending on the desired effect. Coatings, such as paint or clear coatings, can add additional visual appeal and protection to the molded part’s surface.

Optimizing Process Parameters

Achieving the desired surface finish in TPU injection molding requires careful optimization of process parameters. Mold manufacturing companies analyze and adjust key variables, including injection speed, melt temperature, cooling time, and pressure, to achieve the desired surface quality while minimizing defects.

Proper control of process parameters helps ensure proper flow and filling of the TPU material into the mold cavity, minimizing the occurrence of surface defects such as flow lines, warping, or sink marks. Mold manufacturers utilize their expertise and experience to fine-tune these parameters, optimizing the injection molding process for the desired surface finish and aesthetics.

Post-Molding Operations and Finishing

In some cases, post-molding operations and finishing processes are employed to further enhance the surface finish and aesthetics of TPU injection-molded parts. Mold manufacturing companies may employ techniques such as trimming, deburring, or sanding to remove any excess material or imperfections from the molded part’s surface.

Additionally, mold manufacturers may employ secondary processes such as painting, laser etching, or pad printing to add decorative elements or branding to the surface of the molded part. These post-molding operations and finishing processes help achieve precise details, vibrant colors, or customized designs on the surface of the TPU injection-molded parts.

Quality Control and Inspection

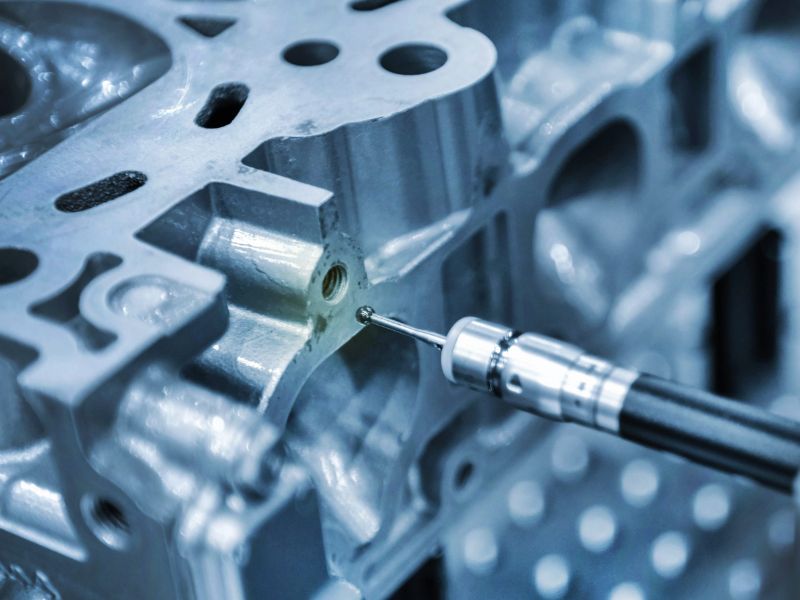

Quality control and inspection are integral to ensuring the desired surface finish and aesthetics in TPU injection molding. Mold manufacturing companies implement stringent quality control measures to verify the surface quality of the molded parts. This includes visual inspections, dimensional measurements, and functional testing to assess the surface finish, dimensional accuracy, and overall quality of the parts.

By maintaining rigorous quality control standards, mold manufacturers can prevent defects and deviations in surface finish, ensuring that the molded parts meet the specified aesthetic requirements. Any surface imperfections or deviations from the desired surface finish can be identified and addressed promptly, guaranteeing the production of high-quality TPU injection-molded parts.

Conclusion

Surface finish and aesthetics are critical aspects of TPU injection molding, contributing to the overall quality and appeal of the final product. Mold manufacturing companies play a vital role in achieving the desired surface finish by employing various techniques such as tooling design, mold surface preparation, process optimization, and post-molding operations. Through careful attention to these factors and stringent quality control measures, mold manufacturers are able to deliver TPU injection-molded parts with precise surface textures, smooth finishes, and enhanced aesthetics that meet the aesthetic expectations of their customers. By prioritizing surface finish in TPU injection molding, mold manufacturing companies can ensure customer satisfaction and create products that stand out in the marketplace.